Owning a generator means having peace of mind that you can access power whenever you need it. A standby generator can support your household or business during emergencies, and a portable generator may be the key to getting power to a job site or off-the-grid gathering. Regular Generac generator maintenance will ensure your equipment is in good working order and you are not left in the dark.

Why Generac Generator Maintenance Is Important

After investing in a standby or portable generator, you will want to protect your equipment with regular maintenance. Undetected issues can grow over time, putting your generator at risk of low performance or expensive damage. Regular maintenance will help you catch hazardous problems before they get out of hand.

Whether you have a home generator ready in case the power goes out or use your generator regularly on a job site, having knowledge of Generac generator maintenance is wise. Take the time to investigate your specific generator, the parts it contains, and the warning signs you should look for when using your equipment. Once you have identified areas of concern, Generac maintenance kits can help you with your equipment’s upkeep.

5 Tips for Generator Maintenance

While each generator may have specific needs, you can do a few things to regularly keep up with your Generac generator maintenance, including:

- Check error codes

- Regularly change oil and oil filters

- Replace air filters

- Check connections

- Do load bank testing

1. Check Generator for Error Codes

One of the easiest ways to monitor your Generac generator maintenance is to pay attention to your equipment’s error codes. If your generator isn’t working quite right, the error codes are the first place to check.

These alphanumeric or numeric identifiers on the control panel will help pinpoint the problem, helping you avoid wasting time looking for the issue. Understanding Generac generator issues and error codes helps save time and stress. Some of the most common generator error codes include:

- Overheating

- Low oil

- Overload

- Overcrank

- Battery power

There is no need to panic if you see an error code on your generator. Your machine’s Generac diagnostic manual will help you decipher what the specific error is and how to address it. If you are still unable to fix the problem, contact a trusted Generac generator technician to ensure your equipment is repaired properly.

2. Change the Generator Oil and Filter

Just like your car, you should change your generator oil on a regular basis to ensure the engine works well. Experts recommend changing the oil in your generator every 50 to 200 hours of operation, or every two years. You will want to change your oil more frequently if you use your generator daily or for an extended period. Changing your generator’s oil is a simple process essential for good Generac generator maintenance.

How to Change Your Generator’s Oil

Before removing any parts to access your generator’s oil, we recommend gathering your supplies.

Step 1: Place an oil pan underneath your oil drain and open the drain tube near the bottom of the motor.

Step 2: Generator oil should start dripping into the pan. Once it has all drained out, you are free to close the drain.

Step 3: Find the oil filler tube, use a funnel to add generator oil, and then measure the oil level with a dipstick.

When you change the oil, we also recommend replacing the Generac oil filter to keep your equipment running well. Your user manual will indicate the specific type and amount of generator oil and the oil filter you should use for your particular machine.

3. Examine Your Generac Air Filter

The generator air filter is an essential element that protects your engine, so checking and replacing these filters is an important step in regular maintenance. Particles, dust, and debris can get into your generator’s engine and cause damage, but filtering the air keeps those harmful elements out of your machine.

Without proper air filter maintenance, your generator could lose power, experience damage to internal components, or use more fuel than it typically needs. Changing your air filters as part of your Generac generator maintenance will ensure proper and protected airflow.

You should change your generator’s air filter every 400 hours or every four years, whichever comes first. Still, check the filters on a regular basis to make sure they are not clogged and replace more often if needed.

4. Inspect All Generator Connections

A generator is a complex piece of machinery with many parts working together. When performing Generac generator maintenance, it is important to check all connections within the generator to ensure everything is functioning well.

Your generator maintenance schedule should include checking several connection points, including:

Fuel lines in gas-powered generators

Fuel and water separators in diesel generators

Battery cables and connections

Wiring/electrical system

By ensuring each connection is secure and working well, you can keep your generator running and prevent problems in the future.

5. Perform a Generator Load Bank Testing

After performing all the necessary checks and conducting thorough Generac generator maintenance, you want peace of mind that everything is in working order. A load bank test can be the final step, giving you the confidence to know your generator is ready for any job or emergency that may come up.

A load bank test checks how your generator handles specific load situations by using a tool called a load bank, which simulates different electrical loads. A monthly load bank test will prove that your maintenance has paid off and your generator is good to go at a moment’s notice.

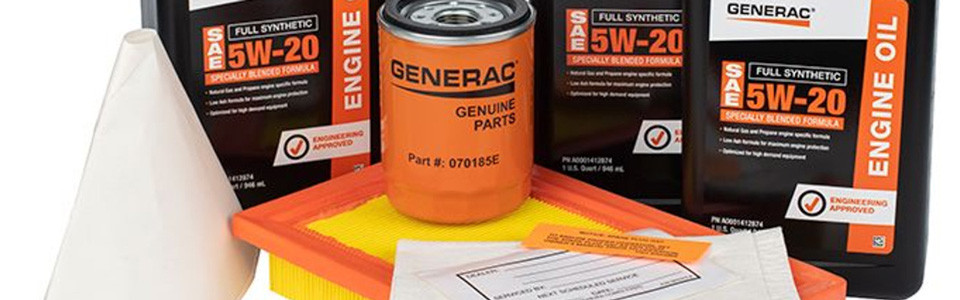

Replacement Generator Parts

Replacing faulty or damaged generator parts is a natural step to keeping your generator working well. If you need a replacement part during your Generac generator maintenance, be sure to get genuine OEM parts for the best results.

Purchasing from Generator Magic eliminates the guessing game of when you will receive your product with real-time inventory of our generator parts. For timely delivery that will allow you to repair your generator quickly, choose an authorized dealer that has genuine parts in stock.

Regular Generac generator maintenance does not have to be daunting or overwhelming. With routine examination and upkeep, your generator will be a reliable source of power for years to come.