When it comes to powering up a generator, one crucial component that often gets overlooked is the carburetor. Without a functioning carburetor, your generator may not start or run inefficiently, resulting in wasted fuel and potential damage. Let’s dive into everything you need to know about generator carburetors, from how they work to common issues and maintenance tips.

What is a Carburetor?

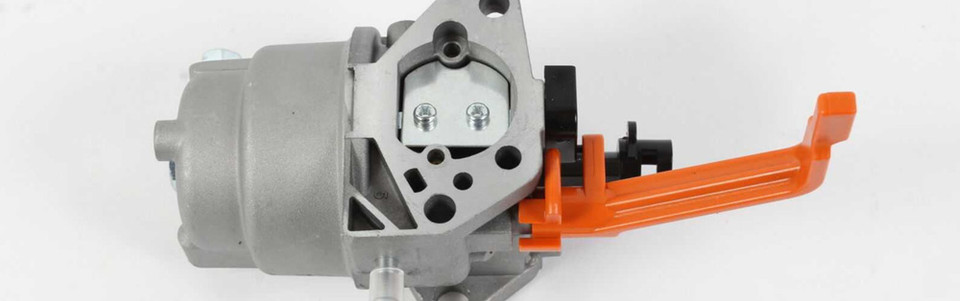

A carburetor is a mechanical device that mixes air with a fine spray of liquid fuel, creating a combustible mixture for the engine. In generators, carburetors are commonly found in small to medium-sized units, especially those powered by gasoline or propane. The primary function of a carburetor is to control the air-fuel ratio delivered to the engine. This ratio is crucial for efficient combustion and optimal power generation.

Why is a Generator Carburetor Important?

The carburetor is a critical part of your generator.It is the heart and soul of your generator's engine, responsible for mixing the perfect combination of air and fuel to ignite the combustion process. Without a properly functioning Generac carburetor, your generator will struggle to start or may run inefficiently, wasting fuel and potentially causing damage. This small yet mighty device is the key to keeping your generator running smoothly and reliably.

The internal working mechanism of a carburetor is a fascinating process that ensures the perfect mixture of air and fuel to power your generator. As air enters the Generac carburetor, it passes through the throttle valve, which regulates the flow. Fuel is then drawn into the carburetor from the fuel tank, where it mixes with the incoming air. This mixture is then delivered to the engine's combustion chamber, where it is ignited to generate power.

The carburetor uses various components such as jets, needles, and floats to control the flow and ratio of air and fuel. Understanding this intricate process is essential for maintaining and troubleshooting your generator's carburetor.

The 3 Kinds of Carburetors Found in Generators

- Fixed-orifice carburetors

- Float-type carburetors

- Electronic fuel injection

Common in smaller generators, fixed-orifice carburetors have a fixed opening through which air flows, and fuel is drawn in through a venturi effect.

Float-type carburetors are found most commonly in many portable generators and use a float to control the fuel level. As fuel decreases, the float opens a valve to allow more fuel into the carburetor.

Electronic fuel injection (EFI) is a type of system installed in modern generators that provides precise control over the fuel-air mixture based on various engine parameters.

Common Generator Carburetor Problems

Generator carburetors can experience a range of problems that can disrupt the smooth operation of your Generac generator. One common issue is a clogged Generac carburetor, which can occur due to debris or dirt buildup in the fuel or air passages. This can result in restricted fuel flow and poor combustion, leading to starting issues and rough running.

Another problem is a stuck or faulty float, which can cause fuel to overflow or not enter the carburetor correctly. Other issues may include a worn-out needle valve, a faulty gasket, or a malfunctioning choke. Understanding these common problems is crucial for diagnosing and addressing any issues with your generator carburetor.

How to Keep Your Carburetor Working Its Best

Maintaining the peak performance of its Generac carburetor is paramount to ensure that your generator operates at its full potential when called upon. Regular care and attention to this essential piece of machinery can not only extend the life of your generator but also guarantee its reliability during critical times.

The top three aspects for maintaining peak performance in your generator are:

- Inspections

- Cleaning

- Fuel quality

Periodic inspections can identify clogs, leaks, or damaged components. Addressing these promptly can prevent more significant problems. Schedule routine visual inspections of the Generac carburetor for any signs of wear, corrosion, or damage. Look for loose connections and leaks, and ensure all components are securely in place.

Cleaning the carburetor is essential to remove deposits and debris affecting its performance, while regular adjustments ensure the optimal air-fuel mixture for combustion. Periodically clean the Generac carburetor to remove accumulated dirt, debris, and varnish that can hinder its performance. Use carburetor cleaner or a specialized cleaning solution to dislodge and clean any clogs in the jets and passages.

The quality of fuel directly impacts the carburetor's performance. Use high-quality, clean fuel in your generator. Stale or contaminated fuel can lead to clogs and affect the carburetor's efficiency. Consider using fuel stabilizers if the generator is not used frequently. Inspect the fuel lines and filters regularly. Replace any old or clogged fuel filters and ensure that the fuel lines are free from leaks or blockages. A clean and well-maintained fuel system contributes to the Generac carburetor's longevity.

The Importance of Quality Parts in Your Generator

Using quality parts and regularly servicing your generator carburetor can significantly impact its performance and lifespan. Quality parts ensure that your Generac carburetor operates efficiently and effectively, reducing the risk of issues and breakdowns. Regular servicing allows you to catch any potential problems early on and address them before they cause significant damage.

By investing in quality parts and scheduling regular service, you can ensure that your generator carburetor continues to run smoothly, providing you with reliable power when you need it most. Don't underestimate the impact of quality and maintenance on your generator and the performance of your Generac carburetor!

How to Choose Quality Parts for Your Generator

When it comes to choosing quality parts for your generator carburetor, there are a few key factors to consider:

- First and foremost, make sure you purchase parts from a reputable supplier or manufacturer. Look for companies with a track record of providing high-quality products and excellent customer service. Reading customer reviews and seeking recommendations can also help determine the reliability and performance of different parts.

- Additionally, it's essential to consider the specific needs of your generator. Not all Generac carburetor parts are universal, so be sure to check compatibility with your generator's make and model. This will ensure a proper fit and optimal performance.

- Lastly, don't forget to inquire about warranties and guarantees. Reputable manufacturers often stand behind their products and offer warranties to protect against defects or premature failures. A warranty can provide peace of mind and assurance that you are purchasing a reliable and long-lasting part.

At Generator Magic, our Generac parts are always sourced directly from the manufacturer and are never after-market. You'll find the quality, dependability, and return on your investment that you deserve when you shop with us. Whether you're looking for maintenance kits or generator air filters, we guarantee you'll find exactly what you need to keep your generator running smoothly at Generator Magic.